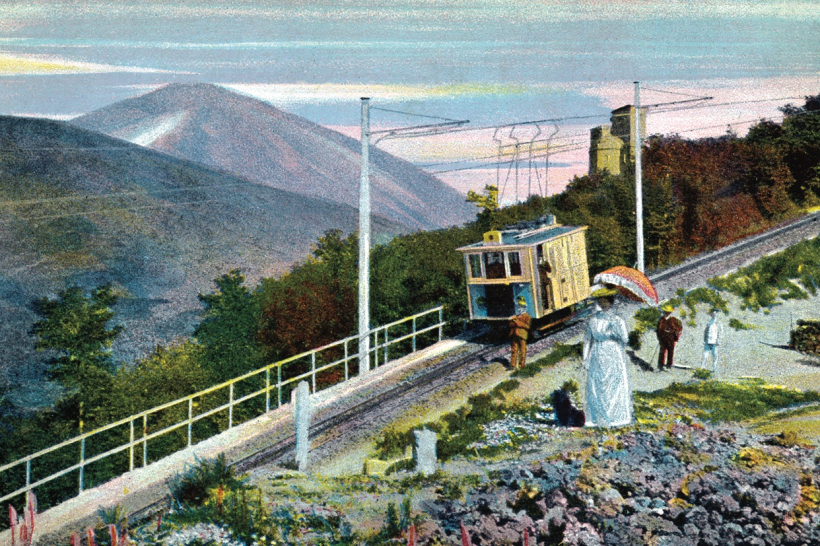

The 19th century postcard depicts electric railway in Italy

History of railways

29 stycznia 2021

The 19th century postcard depicts electric railway in Italy

Despite being very small, it did not resemble the present-day electric locomotives and was able to reach a speed of 4 mph (7 km/h) only, it was received enthusiastically by the inhabitants of Berlin and soon it carried about 80,000 people. From the beginning of the 20th century, countries with highly developed technology took care to develop electric traction. Due to the peculiar urban traffic conditions, at the end of the 19th century an intense development of urban electric rail (tramways) commenced.

Ernst Werner von Siemens (1816-1892) - one of the most outstanding electrical engineering inventors

Interesting but defective

It is true that in previous years similar structures were built, for example, Thomas Davenport’s locomotive from 1834; however, due to their imperfection they were not widely appreciated. The main defect of Davenport’s design and at the same time a difference compared to the locomotive built by Siemens was the method of power supply. The locomotive presented in Berlin was supplied with 150V DC from a third rail. On the other hand, Davenport’s vehicle was supplied from batteries which went flat quickly, so the range of the locomotive was very small.

A similar structure called “Galvani” was presented by Robert Davidson in 1841. However, it had a drawback identical with the previous one, that is, it was supplied from a battery, which was even illustrated by its name given after Luigi Galvani whose research contributed to the construction of the first battery in the world. Another vehicle which was a milestone in the development of electric locomotives was Leo Daft’s locomotive of 1883. Its name – the “Ampère” – was also a tribute to the outstanding scholar. A 30 HP two-ton, two-axle locomotive, supplied from a third rail, was the first locomotive in the world to pull a standard railway carriage.

Quick return on electrification investments

In connection with the many benefits offered by electric rolling stock compared with steam locomotives, it gained popularity very quickly. First of all, it consumed about 5 times less energy, which considerably reduced the costs of transport. In addition, it did not have a “dead weight”, that is, the tender (a box in which coal was transported), and the water or liquid fuel tank. It is true that the electrification of railway lines was a very cost-consuming investment but the financial expenditure required for the construction of the traction soon generated a return in a relatively short time. This is why electrification was undertaken on lines where traffic intensity was high as such lines would generate measurable benefits related to the change in the mode of vehicle supply within the shortest time. Of course, they were mostly urban lines or lines from the neighbouring cities and towns to the centre of large agglomerations. Such routes had high traffic, and the dense network of stops was another element conducive to electrification.

Fast, environment-friendly and economical

Electric locomotives could develop the maximum speed in a very short time and in addition they did not require time-consuming start-up activities as in the case of steam locomotives in which a fire under the boiler had to be lit up several hours before the trip. Electric locomotives had another important advantage: they did not emit pollutants. In addition, steam locomotives required the best quality coal producing high calorific value as fuel while power stations used less efficient fuel to produce energy, not to mention that electricity could be supplied from “clean”, renewable energy sources, such as, for example, hydroelectric power plants.

Ernst Werner von Siemens' electric rail at the Great Industrial Exhibition in Berlin in 1879

Electric drive – the best solution for mountainous areas

Wide options for the use of electrically-powered rolling stock were also seen in destinations where it was difficult to supply coal. Those were mainly mountain areas with numerous tunnels (the smoke emitted by the locomotive could be dangerous) and good access to hydroelectricity. Switzerland, the leader in electrification, can be quoted as an example. The country had strongly inclined and sloping routes, and in addition had no coal resources of its own, which was a reason for rapid development of this method of supply.

Energy from the third rail

The first electric railway lines did not use overhead traction that is known in the present times. The locomotive built by Siemens or the first tramway line in Berlin, dating back to 1881, were supplied with electricity from rails. Siemens’ vehicle used a third rail, similar to that used in the metro nowadays, through which power was supplied to the motor. It was installed between the rails on which the vehicle ran. The first tramway in the world was supplied quite differently, but the system had nothing in common with the overhead network either. In that case, electric current was supplied to the motor directly from the rails on which the train set moved. One rail was a positive pole and the other – a negative one. It is easy to guess that the solution was considerably far from perfect. Firstly, the rails had to be ideally isolated from each other, which posed a problem, among other situations, on interchanges, and secondly – just as in the case of the “classic” third rail – it could be dangerous to people. Insofar as this kind of danger is practically non-existent in the metro (trains run in underground tunnels to which third parties have no access), with the classic ground railway such close proximity of a rail conducting current can be extremely dangerous.

Therefore, new improved solutions to enhance safety were developed. In addition, they were much more useful. Soon the first pantographs capable of supplying current from overhead traction were invented. The structures were not perfect but they significantly improved the level of passenger safety. The overhead traction also enabled the use of higher voltage and thus – installing more powerful electric motors in vehicles.

Problems with direct current supply

The first electric locomotives were supplied with direct current, mainly in connection with the fact that tramways in the past were also supplied with DC. Alternating current at that time was not yet known and after it was invented the scientists had scarce information about the new system of supply, which is typical of “inventions”, and did not fully trust it. Therefore, normally direct current was used. However, apart from pluses the solution had a number of serious drawbacks. First of all, direct current cannot be transformed, that is, its voltage cannot be modified by means of a transformer, as is the case with alternating current. Thus, transmitting relatively low voltages was very burdensome with regard to the size and weight of power cables since while voltage dropped the cable supplying power to the locomotive needed to have larger cross-section, which made them heavier and thus more expensive.

“Returning” the received energy

Another problem was the impossibility to considerably increase the voltage of direct current supplied to locomotives, because the insulating materials available at that time were not capable of performing their role effectively having reached certain voltage. Moreover, according to the formula used to calculate electric power, this value corresponds to resistance multiplied by the current strength square. Therefore, as the current strength increased, the losses in transmission also grew. Increasing voltage in alternating current traction networks could minimize transmission losses as the same power could be transmitted at a lower value of current strength. Another material benefit resulting from the introduction of electric traction is the recovery of electrical energy. In this process the locomotive, when braking, “returns” the previously collected energy to the traction network. This is due to the fact that every electric motor can work as an electric generator. It is enough to set the rotor, previously driven by electric energy, in motion by means of the rolling wheel sets to produce voltage on the stator and make the motor operate in the reverse mode. Of course, the rolling stock must be equipped with special units allowing it to transmit the recovered energy back to the network so that it could be supplied from the same network to another vehicle. However, quite frequently, in particular in older locomotives, the energy recovered during braking is lost, that is, converted into heat by resistors. This process also makes a locomotive braking system working similar to engine braking in cars. As a braking method, recovery is advantageous mostly because the materials which should stop the train set by friction (brake inserts, discs, etc.) do not become worn out.

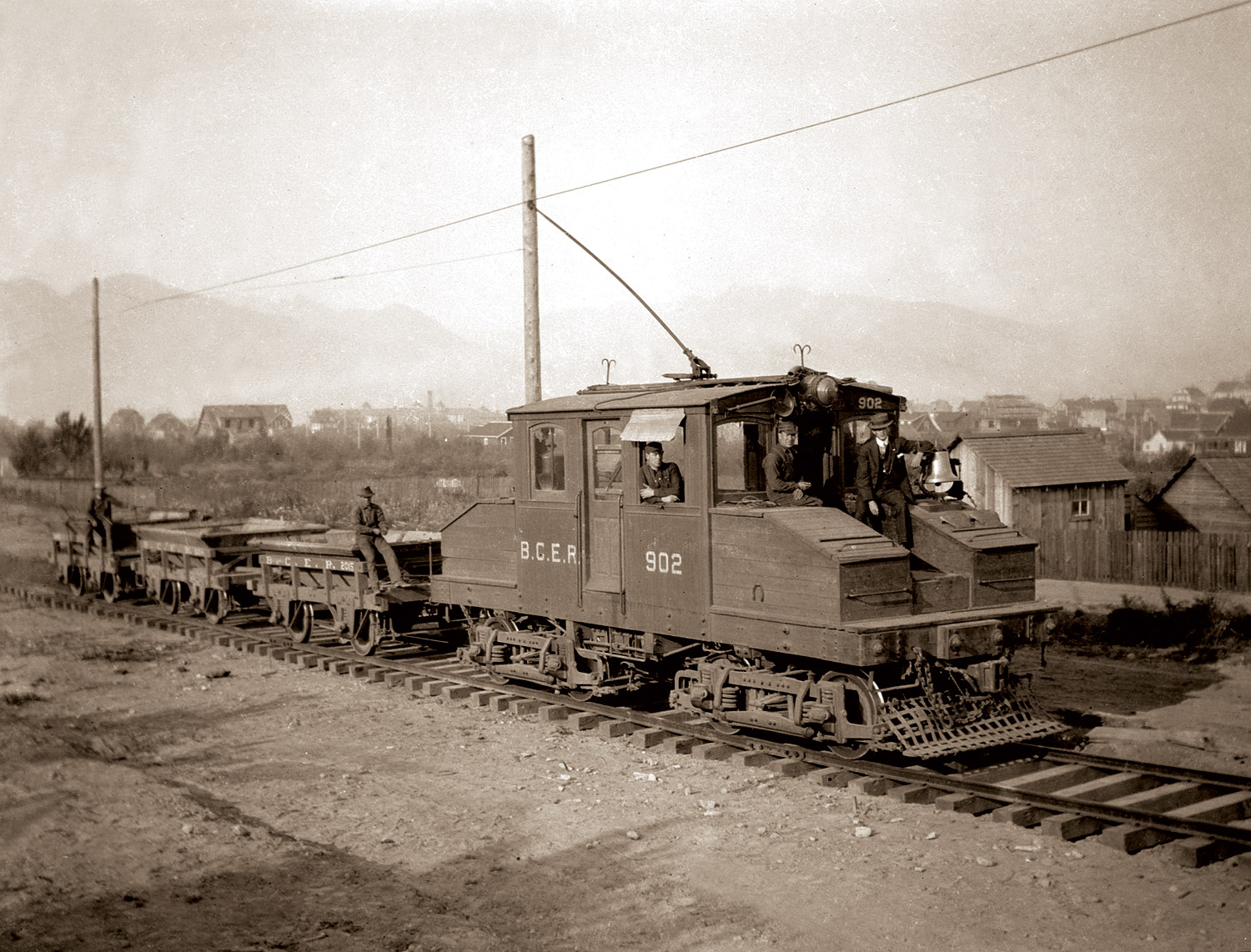

An electric locomotive with a bow collector - first half of the 20th century

Development at a tremendous speed

Electrically-powered vehicles and their supply systems developed at a dizzy pace. As soon as 24 years after the presentation of an innovative vehicle by Siemens, electric locomotives could develop speeds of over 124 mph (200 km/h). An example of such an electric locomotive was a vehicle which in 1903 reached 126 mph (203 km/h) on the route between Zossen and Marienfelde. It was supplied with alternating, three-phase current with a voltage of 10 thousand volts. Regrettably, the construction of the traction network was very complicated and designing a network interchange turned almost impossible. Each of the three phases required a separate cable. Therefore, the traction network consisted of 3 lines parallel to the carriage which supplied energy by means of 3 pantographs installed on the vehicle’s roof. Of course, this design had no future but it demonstrated the huge potential of electrically-powered railway vehicles. Further development of rail vehicle electric supply systems was overwhelming. First, the lines expected to generate the fastest return on investment were electrified. This regards mostly routes with increased traffic intensity and mountain routes (in Switzerland 100% of the lines are electrified).

Different systems of supply

Nowadays, the world knows many methods of supplying power to railways. It is difficult to choose the best one. A popular voltage in Poland is 3 thousand volts DC. Basically, this is the maximum voltage which can be supplied from a traction network with regard to the strength of the motors’ insulation and solidity of contact wires. Similar supply systems are in operation, among other countries, in Italy, Spain, the Czech Republic and Slovakia. One of the most popular voltages used by the railway industry is now 25 thousand volts AC with the frequency of 50 Hz. This system has another great advantage, apart from those mentioned before, that is, it can transform the voltage to match its frequency with the frequency of industrial networks (household power sockets also use this frequency). Thus, only a small number of simple traction substations are required and the voltage value will send energy through small diameter (light) cables keeping losses at a low level. This type of supply is used, for example, by Chinese, British, Spanish and Japanese railways. It is worth mentioning that it is also used to supply energy to fast railways (TGV, Shinkansen, and Pendolino).

The largest American electric locomotive owned by the now non-existent company Chicago, Milwaukee, St. Paul and Pacific Railroad, supplied with 3,000 V DC - 1924

Apart from the systems mentioned above, many other systems are also used, though on a considerably smaller scale. Also, 1500-volt DC systems (such as in Australia, France, and India) and 15-thousand-volt AC systems with the frequency of 16 2/3 Hz (such as in Germany, Norway, Sweden, and Switzerland) should be mentioned. Many countries all over the world make use of more than one system of supply. Many countries use different voltage and often both alternating and direct current. However, this necessitates the construction of cost-consuming transformer stations, rectifier stations, etc. and the use of proper rolling stock on selected lines. The second problem is often solved thanks to multi-system vehicles, that is, units which can be supplied by various types of voltage. Obviously, such locomotives are accordingly more expensive.