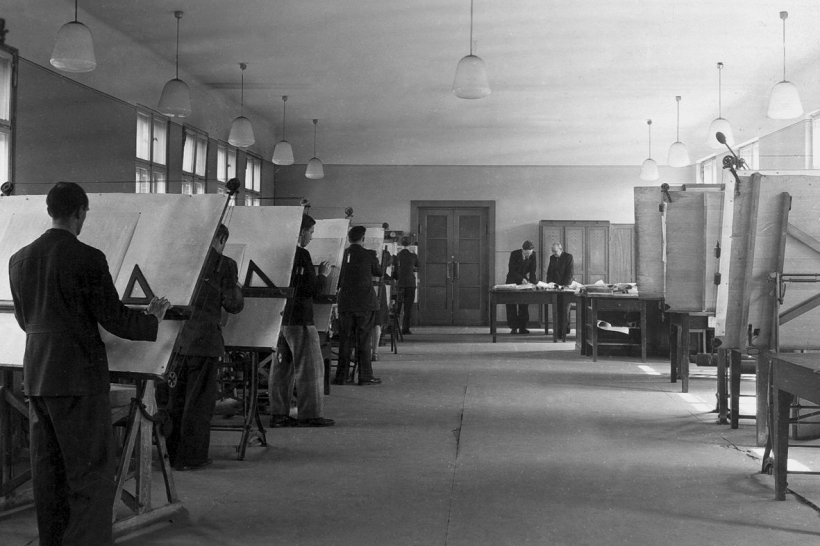

The design office of Zastal in Zielona Góra

History of railways

December 18, 2020

The design office of Zastal in Zielona Góra

Fablok – the First Locomotive Factory

Still in February 1945 the First Polish Locomotive Factory (in short Fablok) in Chrzanów commenced the assembly of steam locomotives of the wartime series BR52 (Ty42). In 1946 the factory released Ty45 steam locomotives (174 vehicles) built on the basis of the pre-war Ty37 model. From 1947 the factory produced Pt47 locomotives (120 vehicles) designed on the basis of the Pt31 model. In subsequent years Fablok manufactured new steam locomotives of TKt48 series (115 vehicles), Ol49 series (116 vehicles), TKh Ferrum 47 (437 vehicles), TKb 1B “Baziel” (20 vehicles), fireless TKb 1U (36 vehicles), T2D SLA TKp “Śląsk” (390 vehicles) and “WP” steam locomotives for export to India (30 vehicles). The last locomotive left Fablok in 1963. It was a TKp “Śląsk” locomotive with construction number 6296.

In 1952 Fablok commenced the production of diesel locomotives for the needs of PKP and industrial plants, starting from the Ls40, followed by the SM42 shunter (1,822 vehicles). The last diesel locomotives left the factory in 1992. In total 4,868 diesel locomotives of various types were produced in Chrzanów. In 1991 Fablok was transformed into a company fully owned by the state. However, the effects of subsequent transformations and changes in organisation were not as expected and in January 2013 the company declared bankruptcy.

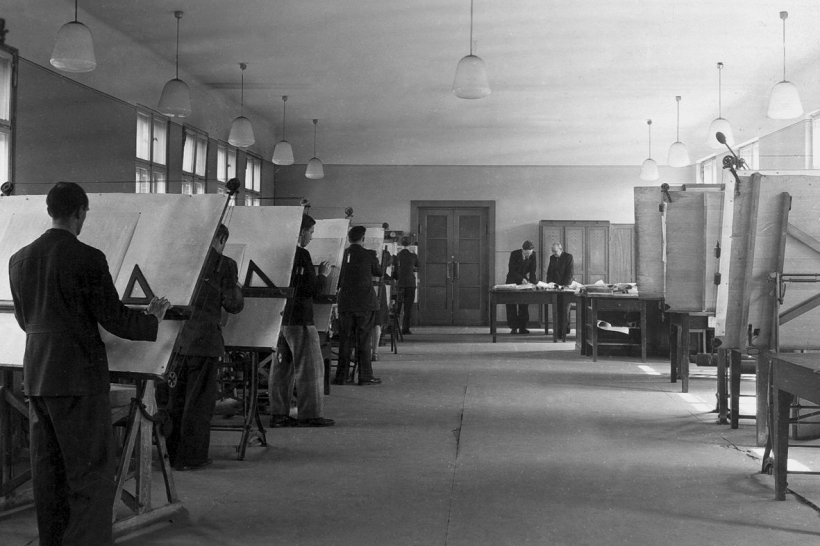

Inside the H. cegielski factory in Poznań

Meanwhile at the the Cegielski Works in Poznań

The H. Cegielski Metal Works in Poznań started their operation from assembling BR52 (Ty42) locomotives, followed by Ty43 (German BR42; 124 vehicles), parallel to Ty45 (258 vehicles). Later they built Pt47 (60 vehicles), TKt48 (82 vehicles) and finally the heaviest Polish steam locomotives – Ty51 (232 vehicles), equipped with mechanical coal feeders (stokers), and “Er” steam locomotives exported to the USSR (895 vehicles). In 1953–1956 the works were named after Stalin and were referred to in short as ZISPO. In 1962 “Cegielski” produced a series of diesel wagons with hydraulic transmission called 5M (SN80; 13 wagons), and in 1970 it launched the production of the 301Da line diesel locomotives (SP45; 265 vehicles) with 1700 HP for the Polish State Railways. In subsequent years 303D diesel loco-motives (Co-Co) and 203E and 203Ea electric locomotives (Bo-Bo+Bo-Bo) were produced. In addition, the factory produced passenger carriages, sleeping cars, couchettes, restaurant cars, and luggage wagons, meant for local traffic, including carriages exported to the USSR, Greece, Yugoslavia, Iraq, Morocco and Hungary. In total 1,751 steam locomotives, 784 electric and diesel locomotives and approx. 14,000 wagons and carriages were released from the factory after World War II. The final decade of the 20th century was a period of structural changes. Restructuring in 1997 resulted in the formation of H. Cegielski – Fabryka Pojazdów Szynowych Sp. z o.o. – a company from the group H. Cegielski – Poznań S.A. Since 2010 the company has been fully owned by Industrial Development Agency.

The assembly of axle-sets at the H. Cegielski Factory in Poznań

ZNTK – the Rolling Stock Repair Workshop

Another manufacturer was the Rolling Stock Repair Workshop in Ostrów Wielkopolski (formerly known as the Wagon Factory). Starting from 1947 all refrigerator cars and from 1948 – four-axle passenger and restaurant carriages were built there. In the mid-1960s the Plant also offered four-axle covered freight wagons, and in the mid-1970s – two-axle covered wagons. The enterprise declared bankruptcy in 2004. The Ostrowiec Plant in Warsaw (formerly WSABP) did not resume the production of rolling stock. On the other hand, the former Ostrowiec Plant in Ostrowiec Świętokrzyski (after 1945 known as Ostrowiec Steelworks, in 1952 renamed as the Nowotko Steelworks and then the Ostrowiec Steelworks again) produced coal wagons and two-axle flat wagons with side boards until 2003. In particular 2Z flat wagons were produced on a mass scale as more than 8 thousand such wagons were assembled in Ostrowiec.

Other factories

The Sanowag Factory in Sanok resumed the production of covered wagons, coal wagons and flat wagons in 1945. It also dealt with repairs of damaged rolling stock. The last tank cars left the factory in 1953. The plant in Chorzów, until 1939 known as the Processing Workshop, and operating as “Osmag” during the war as part of the Reichswerke Hermann Göring concern, despite being considerably devastated, in 1945 was renamed as Mostowagon and resumed production. From 1949 it operated as the Chorzów Steel Structure Manufacturing Plant “Konstal” (in 1997 bought by GEC Alsthom, presently known as ALSTOM). The construction department assembled covered wagons, self-discharging hopper wagons and well wagons which could carry loads weighing 40, 100 and 120 tons. In 1957 an eighteen-axle Schnabel car (17Z) with a loading capacity of 164 tons was produced for the transportation of transformers, and 5 years later – a sixteen-axle car (606Z) with a loading capacity of 230 tons.

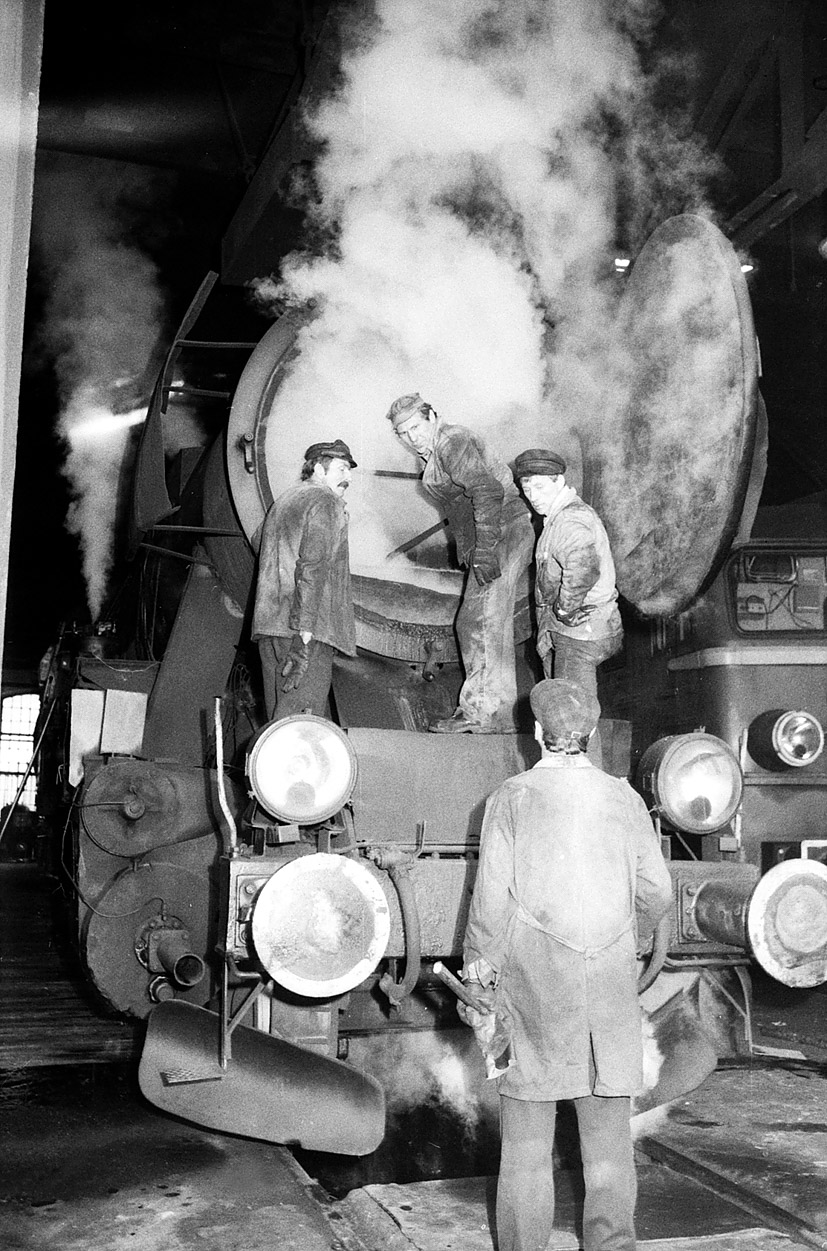

Steam locomotive depot in Iława

In the 1980s, in cooperation with the American company NORCA, Konstal produced Schnabel cars with various numbers of axles: 12, 16, 32 (on 8 four-axle bogies with a capacity of 500 tons) and 24 (on 8 three-axle bogies with a capacity of 250 tons). The range of products also included self-discharging wagons (425V, 902V), filling sand self-discharging wagons (15W, 22W, 401V), container flat cars (213Z), and tankers (450R – for fuel, 451R – for liquefied gas). Currently, the company is the producer of Metropolis metro trains, among other things.

State Railway Car Factory “Pafawag”

Another producer of rolling stock was the State Railway Car Factory “Pafawag” in Wrocław which derived from the former plant Linke-Hofmann Werke AG. It launched the production of German type Klagenfurt coal wagons (2W), modernising their subsequent versions. After 1960 steel-walled coal wagons were produced. The range of products also included four-axle German passenger carriages C4ü42 and self-designed 1A carriages totalling 1,500. The factory was also a manufacturer of 30D43 and 32D43 tenders for steam locomotives. In addition to two-axle coal wagons (7 models), six-axle flat wagons, two-axle covered wagons (28 types), wagons for the transportation of fruit, swine, lime, tank cars for the transportation of cement in bulk (CWL24), sleeping cars, mail and luggage carriages were assembled. In the 1960s the production of four-axle passenger carriages of Y standard (111A, 112A), and local traffic carriages (102A, 120A) was launched. Pafawag specialised in the production of electric rolling stock. In 1953–1957 it manufactured 8 locomotives of E110 series (Bo-Bo) for the reconstructed Warsaw Railway Junction and an identical number of 2E locomotives for the needs of mining industry. Another product of the factory was an electric locomotive of 3E type, based on a Soviet WL21M design, originally identified by PKP as E06 series (ET21). In 1956–1971 its delivery volume amounted to 658 locomotives.

EW55 – Polish electric multiple units

Following the production of 20 vehicles of E53 type (EW53) in 1954– –1956, in subsequent years (1958–1962) the factory manufactured electric multiple units EW55 (72 units) that were completely designed in Poland. They were adapted to lines with high-level platforms. The EN57 (1961–1991; 1358 vehicles) could be used on routes with any platform height. In 1990–1994 its modernised version (54 vehicles) was produced and it still forms the core of electric rolling stock in Poland. This vehicle was used as a model for electric trains in the Tri-City (1974–1980) and on the electrified Kraków–Zakopane (1993–1996) line. In 1969–1972 the Electric Commuter Railways in Warsaw received 40 vehicles which replaced the long-serving carriages from 1927.

Locomotives

In the early 1960s PKP imported 20 EU06 type locomotives from England and bought a licence to produce them. In 1965–1974 Pafawag produced 240 electric locomotives identified as EU07 (4E). In addition, in 1972–1976, 15 EP08 locomotives were built for the Warsaw–Poznań line and their maximum speed was 87 mph (140 km/h). The ET22 locomotive (Co-Co, 201E) produced by Pafawag in 1969–1989 (1184 vehicles) was a completely Polish design. In the following years, 47 locomotives of the EP09 type (Bo-Bo, 104E) left the factory by 1997. From 1996, when PKP declared its intention to buy new electric locomotives, 42 EU11 one-system locomotives were built.

The transformation of Pafawag

In 1997 the company was sold to the Adtranz concern and renamed as Adtranz-Pafawag Sp. z o.o., and since 2000 it has been known as Bombardier Transportation Polska Sp. z o.o. The locomotives produced in Wrocław under the Bombardier logo can be seen on routes in Greece, Germany, Poland, Switzerland, Sweden and the USA. The F160 DC locomotive for freight carriages on difficult routes in the Alps was produced for the Italian Trenitalia railways. ICE trains in operation in Germany and the Netherlands, and Talgo locomotives used in Spain, are also equipped with subassemblies manufactured in Wrocław. After the war special-purpose wagons, rail cars and their trailers were produced at the Rolling Stock Repair Workshop (ZNTK) in Wrocław. ZNTK Ostróda also experienced a short period of wagon production. In the early 1970s, it launched two-axle flat wagons for the transportation of containers and two-level flat wagons for the transportation of motor vehicles. The plant in Zielina Góra was established within the premises of the Bridge and Steel Structure Factory “Beuchelt & Co”. From 1952 it operated as the Marceli Nowotko Metal Industry Plant “Zastal”. Nowadays, it operates as a joint stock company Zastal SA. Its first products after the war included two-axle tankers and 1L refrigerator wagons. In its history Zastal has produced a total of more than 200 thousand wagons, including two- and four-axle covered wagons, two-, four- and six-axle coal wagons, flat wagons, and four- and six-axle self-discharging wagons. It also manufactured diesel locomotives for PKP, but mostly for the needs of Polish industry.

Continued operations of ZNTK Świdnica

ZNTK Świdnica, deriving from a repair workshop, was transformed in 1951 into Wagon Factory “Świdnica”. One year later, the first batch of four-axle 17W coal wagons was launched and until 1959 several hundred wagons of this type were produced every year. It was a very interesting structure because after all side walls were removed, it could be used as a flat wagon for the transportation of armoured tanks. In 1953 the factory in Świdnica commenced the production of 8R tank cars. The main products were two-axle tank cars (for the transportation of, among other substances, acids, soda lye, crude oil, carbon disulphide, carbon dioxide, phenol, glycerol – 16 types in total) and four-axle tank cars (for the transportation of petrol, tar, mazut, propane-butane, sulphuric acid, liquid sulphur, liquid chlorine, liquid fertilizers, carbon dioxide condensate, 50 types in total – including broad-gauge wagons). A large portion of the products was exported.

The Wagon Repair Workshop in Świdnica (until 1951), now Wagony Świdnica S.A. - welding wagon walls

In 1992 the company was privatized and turned into Fabryka Wagonów “Świdnica” S.A. Six years later most shares were held by the Greenbrier Companies from the USA and the factory was renamed Wagony Świdnica SA. In December 2016 the company from Świdnica was transformed into a limited liability company with Greenbrier Europe B.V. as its sole shareholder.

Rail Vehicle Works

Following the restructuring of ZNTK in Stargard Szczeciński (after 1945 operating on the basis of the local Railway Repair Workshop established in 1859), the Rail Vehicle Works were established in 2000. In the 1960s (in addition to deliveries of tank car chassis for the Wagon Factory Świdnica), they specialised in the production of rail machines, among other things, ballast cleaning machines, ballast distributing and profiling machines, track alignment machines, motor cars, trailers, snowploughs, weed control machines and track tampers. Currently, Rail Vehicle Works produce maintenance trains, electrical power engineering service vehicles, rail tractors, hydraulic platforms, ballast cleaning machines and ballast transport trains, ballast distributing and profiling machines, diesel cars, trailers, bulk material transporters, draisines, shunting tractors, wreck trains and crossover replacement equipment.

PKP launches diesel locomotives

Having abandoned the idea of buying steam engines, given the slim length of the electric network, PKP started to introduce diesel traction. First, three diesel wagons (SD80) with hydraulic transmission and two motors, which could develop a speed up to 81 mph (130 km/h), were bought from OM of Milan, Italy. Fablok in Chrzanów released its first low-power Ls40 locomotives (44 HP) in 1952, based on the pre-war documentation. Fablok also built 300 HP locomotives with a working identification symbol Lwe55. In 1957–1970 the factory released 293 units. In addition, Polish State Railways were a regular customer of Ganz-Mavag – a Budapest-based manufacturer, from which over 20 years, starting from 1956, they bought 575 diesel wagons. Diesel locomotives were also produced by the Cegielski Factory which in 1961–1964 released a series of 13 wagons of 5M350 type (SN80) with hydraulic transmission. The last one was taken out of service in 1979.

Large diesel-powered vehicles

Traction for passenger and freight trains required heavyweight line locomotives that were not produced in Poland. Therefore, starting from 1965, ST43 diesel locomotives manufactured under a Swiss licence were imported from Romania. They were mostly used in freight traffic service but in summer they also pulled passenger trains. Up until 1978, Polish State Railways bought 422 such locomotives.

In the early 1970s diesel traction vehicles carried out 40% of PKP’s shunting work and 17% of transport (steam locomotives – 38%, and electric locomotives – 44%). However, there was a shortage of medium-duty locomotives for passenger train service, on secondary lines. Thus, the SP32 series was bought in 1985–1991 from Romania but it turned out to be very fallible. The requirement for heavyweight shunting locomotives was satisfied by the production of the heaviest diesel locomotives used by PKP, i.e. type 411D, and TEM2 vehicles imported from the Union of Soviet Socialist Republics part of which was used for broad-gauge shunting.

PESA of Bydgoszcz

The former Rolling Stock Repair Workshops (Polish acronym: ZNTK) in a number of cities were converted into new companies producing rolling stock. Rail Vehicles PESA in Bydgoszcz was set up in 2001 after the local ZNTK established in 1851 was privatised. PESA commenced the production of the so-called railbuses, that is, one- and two-car diesel vehicles of the SA series. Its product offer also includes, among other vehicles, electric six- and four-car ELF sets. In addition, PESA deals with the refurbishment of passenger carriages and freight wagons and produces 120Na “Swing” tramways. The company also carries out general overhauls, revision repairs, periodic inspection and refurbishment of locomotives.

PESA Gama Marathon - an electric locomotive with an additional diesel generator

NEWAG of Nowy Sącz and Gliwice

NEWAG in Nowy Sącz was established in 2005, also following the privatisation of the local ZNTK which from 1876 operated as locomotive and wagon repair workshops. Having given up the repairs of steam locomotives in the mid-1960s, the company specialised in repairs of diesel locomotives, passenger carriages, heater cars, ploughs and railway cranes. Using EN57 chassis and bodies in 2005 the works built a series of 8 “Halny” electric traction sets for the Fast Urban Railway in Warsaw. Another example was the “papal train” built in acknowledgement of the pontificate of Pope John Paul II for the needs of the Kraków-Wadowice “papal” line. In the following years NEWAG built Co-Co locomotives and electric and diesel traction sets.The Electric Locomotive Repair Works in Gliwice (today NEWAG Gliwice S.A.) – having built the prototypes of “Dragon” (Co-Co) and “Griffin” (Bo-Bo) locomotives – joined the group of railway manufacturers in 2009. From 2004 the works modernised ET22 locomotives for PKP, thus creating the ET22-2000 series.

Tatravagónka

Wagon Factory Gniewczyna – FWG (formerly ZNTK established in 1982) commenced the modernisation and refurbishment of freight wagons in 1993, and since 1996 it has manufactured such wagons. FWG is also a producer of coal wagons, self-discharging “talbot” wagons, flat wagons and container cars, pocket wagons for the transportation of semi-trailers, containers and vessels. Currently, the company’s shares are held by Tatravagónka of Slovakia.